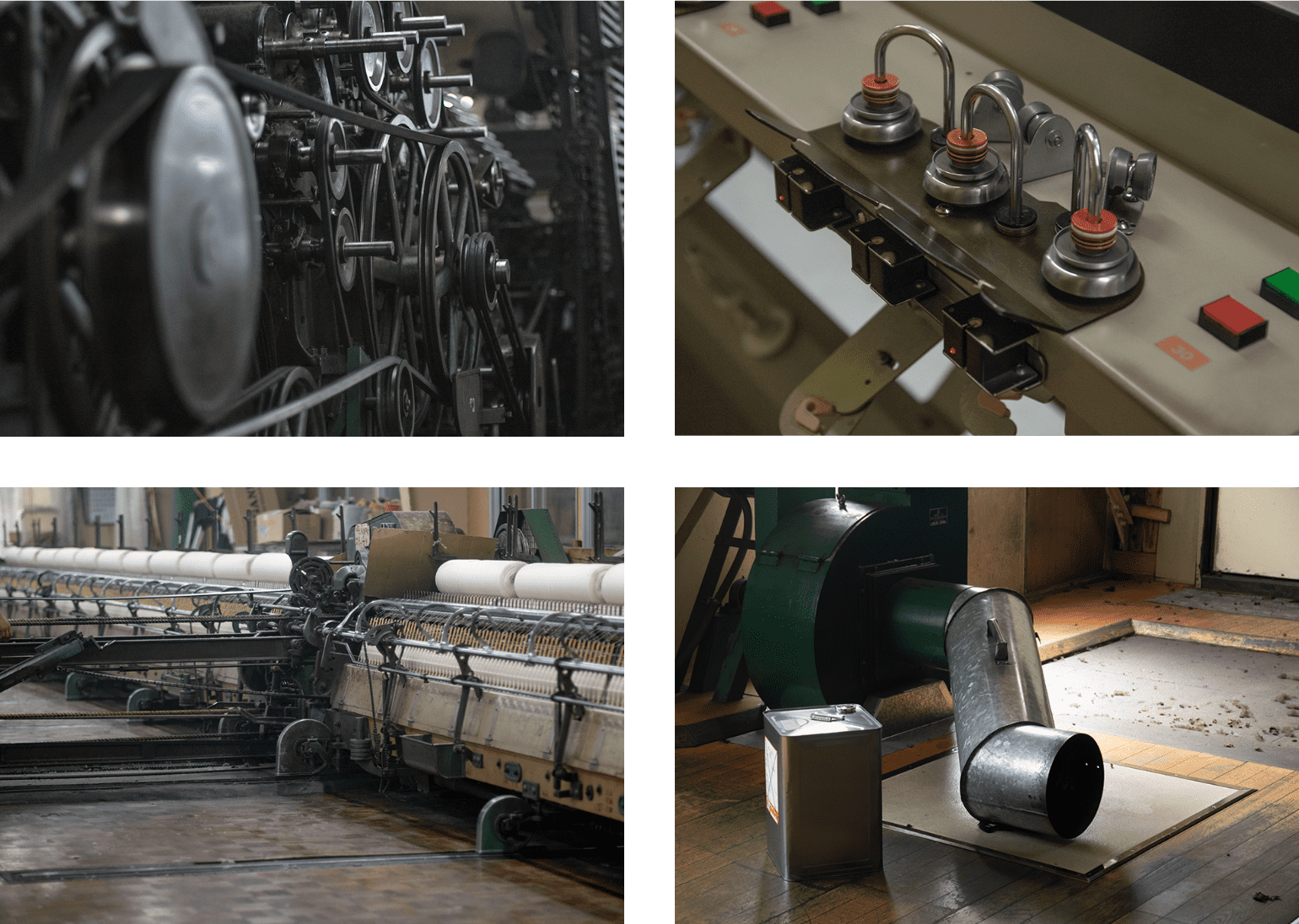

Manufacturing and Commitment

Commitment to yarn and explanation of spinning wool

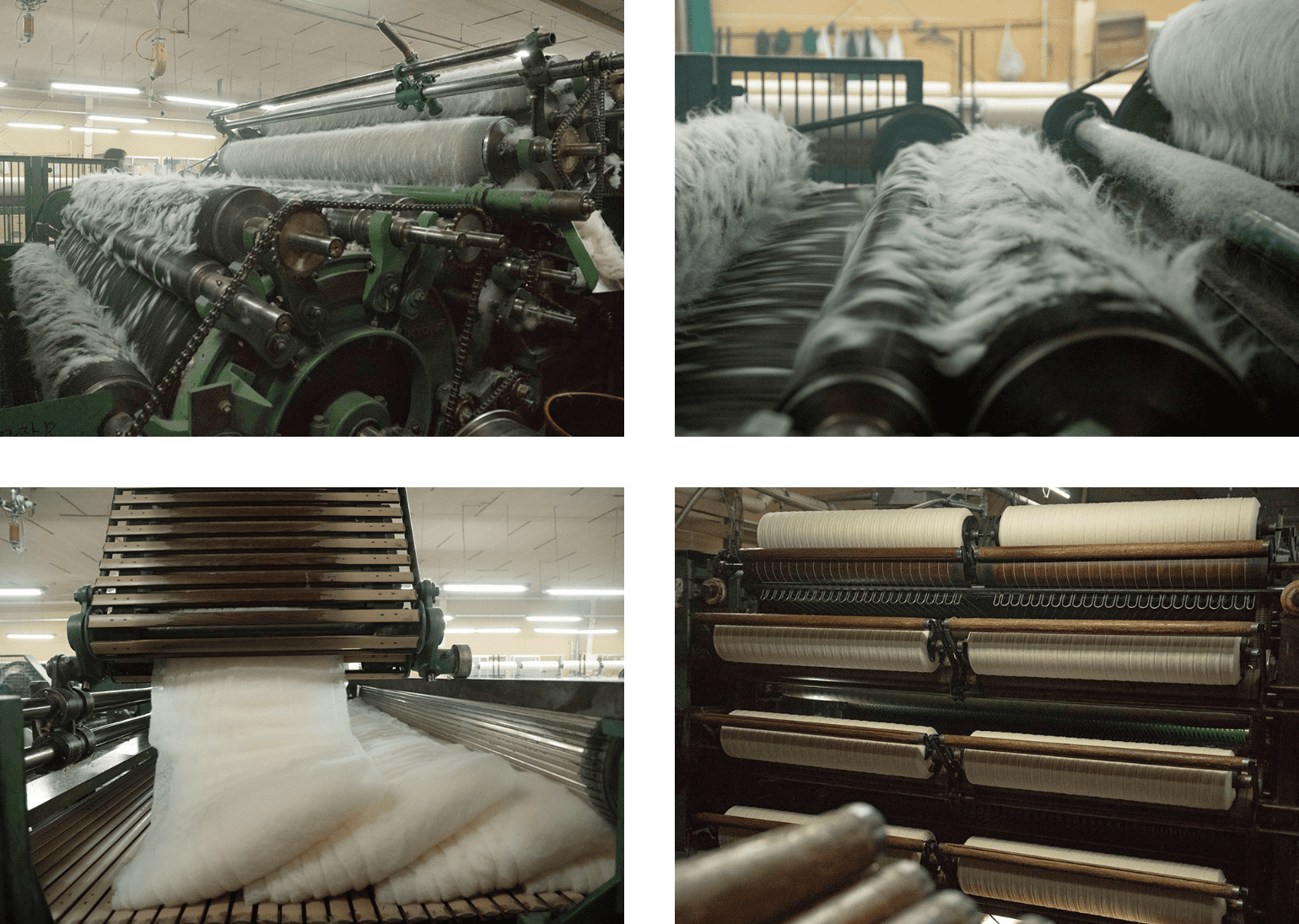

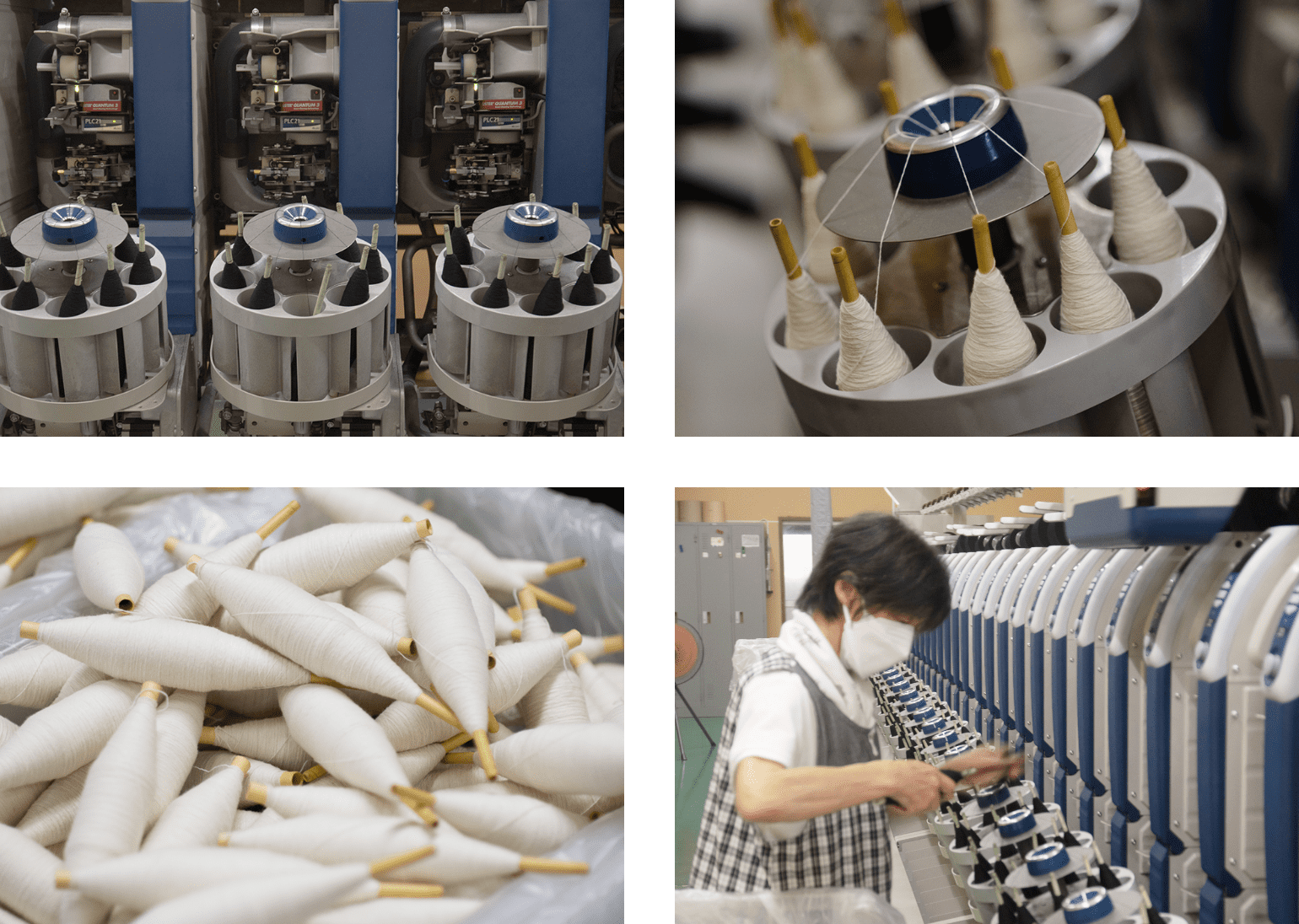

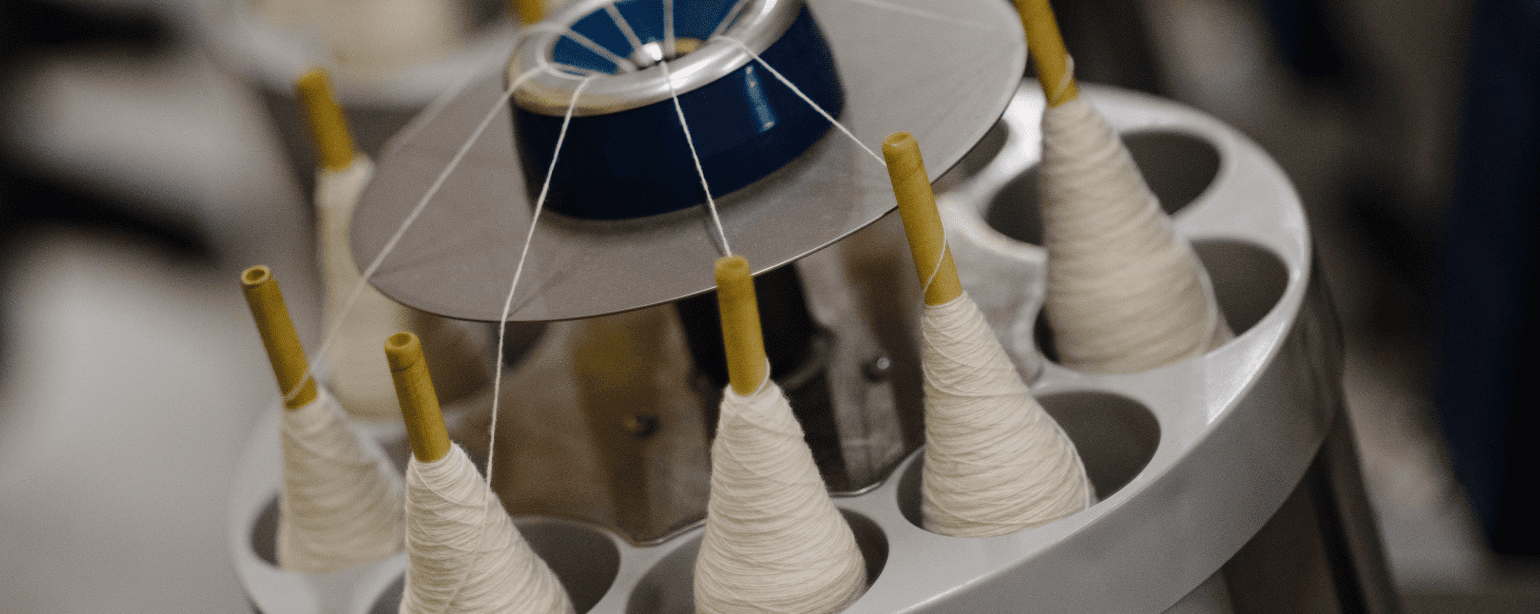

Wool yarns are classified into spun and combed yarns. Woolen spinning, which produces spun yarn, is an industrialized version of handspinning, and corresponds to the kind of yarn that most people imagine. The surface of the yarn is soft and fluffy, and it is soft and light because it contains a lot of air.

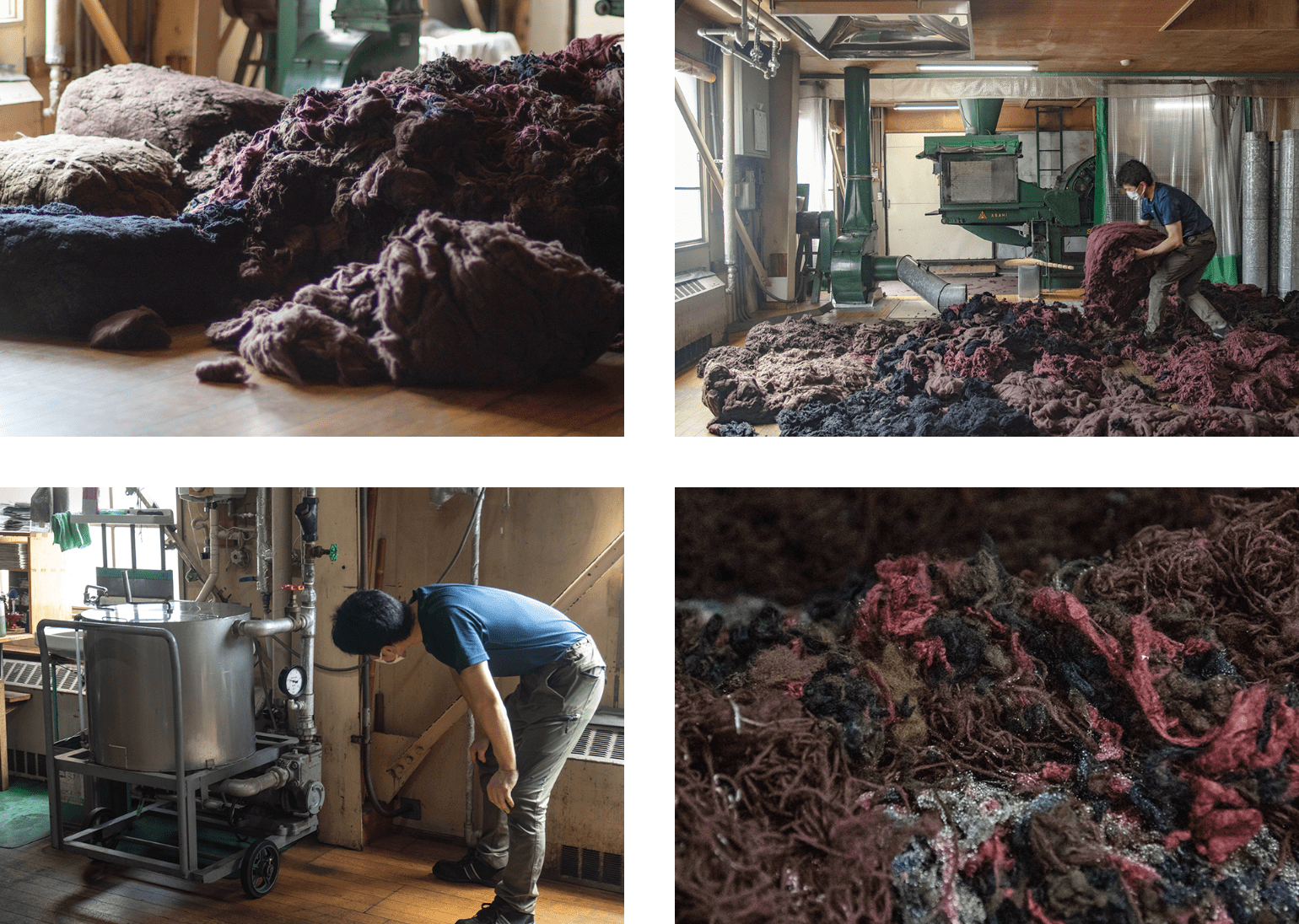

The process of making woolen yarn

The founder

– Tatsuro Ishii -

The late Tatsuro Ishii, founder and first president, was a technological pioneer in Japan's wool industry and was regarded as both a teacher and a god. After graduating from the spinning and weaving department of Tokyo Higher Technical School (known as Kuramae High School of Technology, now Tokyo Institute of Technology), he entered the wool industry by working at an army arsenal. One of his classmates at that time was the late Kazumi Takahashi, chairman of Nippon Felt Co.

After serving in the army for 9 years and 8 months, he worked for Takada Wool Weaving for 1 year and 4 months, Fuji Wool Weaving for 1 year and 5 months, Manchurian Wool Weaving for 3 years and 2 months, Kurihara Boshoku for 10 years and 9 months, and after working as an advisor to Kitabo After working as an advisor to Kitabo, he established his own company, Kogane Wool Textile Co. During this time, he was involved in Marushin Felt and Asahi Fibers, but in each case, he served as a technical leader, and it was largely due to his character to say no when asked to do so.

From the Taisho to the Showa period, Japan was in the midst of a transition from kimono to western-style clothing, and wool weaving technology was noticeably lagging behind. In the midst of this situation, the company was always one step ahead of advanced technology, studying at the University of Leeds in England and visiting Australia to "create woolen fabrics better than those made in England" with passion.

Ltd. (formerly Kurihara Boshoku), and became a leader in the technological improvement of Kurihara Boshoku, which was more like a small factory and had only the technology of spinning and weaving muslin yarn for kimono fabrics and finishing muslin for carpeting, and was behind the scenes in the "big change". He was a behind-the-scenes force behind the "big change. Ishii himself was not greedy and knew how to move forward or backward.

Ishii came to own his own company when he had the opportunity to invite a company to the site of a former junior high school in Koganecho, where he lived. In addition to his business activities, Ishii was also busy taking care of the industry. Tatsuo Ishii believed in the development of the woolen textile industry in Japan. His legacy lives on at Kogane Wool Textile today.